PCB design problems encompass the multifaceted challenges encountered during the creation and assembly of printed circuit boards. These problems arise from the intricate process of PCB layout and the precise alignment of components within tight confines. The difficulties in ensuring accurate trace routing, signal integrity, and thermal management introduce complexities that demand meticulous attention. Such issues not only affect the manufacturability of the PCB but also impact the reliability and performance of the electronic devices they power. Addressing these design challenges is crucial for ensuring the efficiency and reliability of electronic devices. Overcoming these hurdles enables the production of robust electronics capable of consistent performance over prolonged periods. Failure to tackle these design problems can lead to suboptimal device performance, increased production costs, and potential device failures in the field. Therefore, identifying and mitigating PCB design challenges is vital in delivering high-quality and dependable electronic products.

Component placement is a critical factor in PCB design, presenting significant challenges due to space constraints and its impact on functionality. With the increasing demand for compact and multifunctional devices, designers often struggle to effectively utilize limited board space without compromising performance. For instance, industry reports highlight the necessity of strategic placement to avoid components interfering with each other's operation, which can lead to malfunction in high-density designs. Signal integrity is another frequent issue in PCB design, often compromised by improper routing of traces. Poor routing can lead to interference, causing digital signals to degrade, which may result in data errors and device malfunction. Studies indicate that nearly 60% of signal integrity failures stem from inadequate trace routing, emphasizing the importance of precise routing paths to ensure signal reliability. Thermal management is an essential aspect of PCB design, with inadequate heat dissipation leading to overheating and reduced performance. PCBs with poor thermal designs often face high failure rates; statistics suggest that nearly 20% of electronic failures are attributed to thermal issues. Understanding thermal pathways and incorporating features like heatsinks and thermal vias can enhance heat management and improve device longevity.

Optimizing component layout in PCB design is crucial for enhancing circuit performance and reliability. By maximizing efficiency and minimizing trace lengths, designers can significantly reduce the signal path's resistance and inductance. Leading manufacturers employ optimizations such as aligning components strategically to achieve compact designs that support high-speed signal transmission. For instance, grouping power-critical components close to each other can help reduce power loss and enhance overall circuit efficiency. Ensuring effective power distribution is another pivotal solution to PCB design challenges. Implementing ground planes and comprehensive power distribution techniques can greatly enhance a PCB’s performance. Research from technical articles supports this by showing that ground planes reduce electromagnetic interference (EMI) and improve signal integrity. For example, a well-designed ground plane can act as a shield against external noise and provide a stable reference voltage for circuit operations. Utilizing simulation tools like SPICE or Altium Designer can effectively forewarn of potential design issues before moving to the prototyping stage. These tools allow designers to simulate and analyze the performance of their circuits under various conditions, thus identifying potential problems such as overheating or trace routing issues early in the design process. Success stories from users of these tools often highlight their role in reducing iteration cycles and enhancing design reliability, demonstrating their value in modern PCB design workflows.

The integrity of a PCB design relies heavily on performing thorough Design Rule Checks (DRC). DRCs are essential in maintaining design standards by identifying potential issues early in the process. They verify whether your PCB layout adheres to specified limitations, such as trace width and component spacing, and help mitigate errors before they become costly. Most advanced EDA/ECAD tools offer integrated DRC functionalities, enabling designers to ensure their layouts meet the geometric constraints and requirements critical for prototype success. Selecting the appropriate software tools is another cornerstone of effective PCB design. Tools like Altium Designer and Eagle have improved workflows for many professionals, as documented in various case studies. These platforms offer comprehensive features that facilitate complex circuit designs, from schematic capture to auto-routing, and allow for more efficient collaboration within teams. By employing these tools, designers can achieve greater precision and efficiency, ultimately enhancing the overall quality of their PCB layouts. Regular testing and iteration of your designs is a practice that closely correlates with high production quality. By repeatedly prototyping and refining the design, you can address unforeseen issues and align the prototype more closely with the final product. This iterative approach not only results in more reliable PCBs but also helps prevent costly errors during mass production. Repeated testing ensures that the design will perform as expected under various conditions, leading to enhanced performance in the final production run.

When it comes to top-quality customized quick-turn PCB circuit board assembly services, reliability and market reputation are critical factors. A leading provider in this area offers comprehensive services, specializing in ODM and OEM orders with an emphasis on durable and high-performance PCB solutions. Their extensive experience in manufacturing ensures that every project, big or small, receives the detail and precision required for excellence.

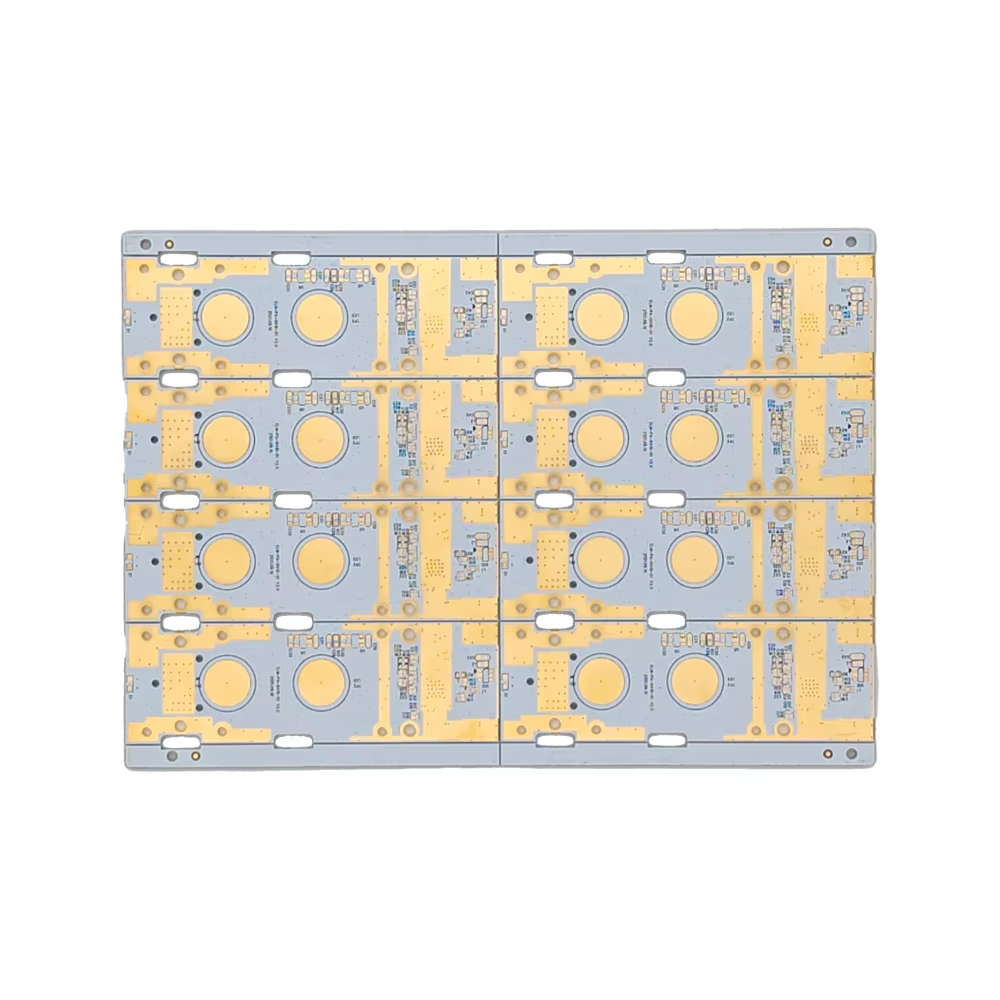

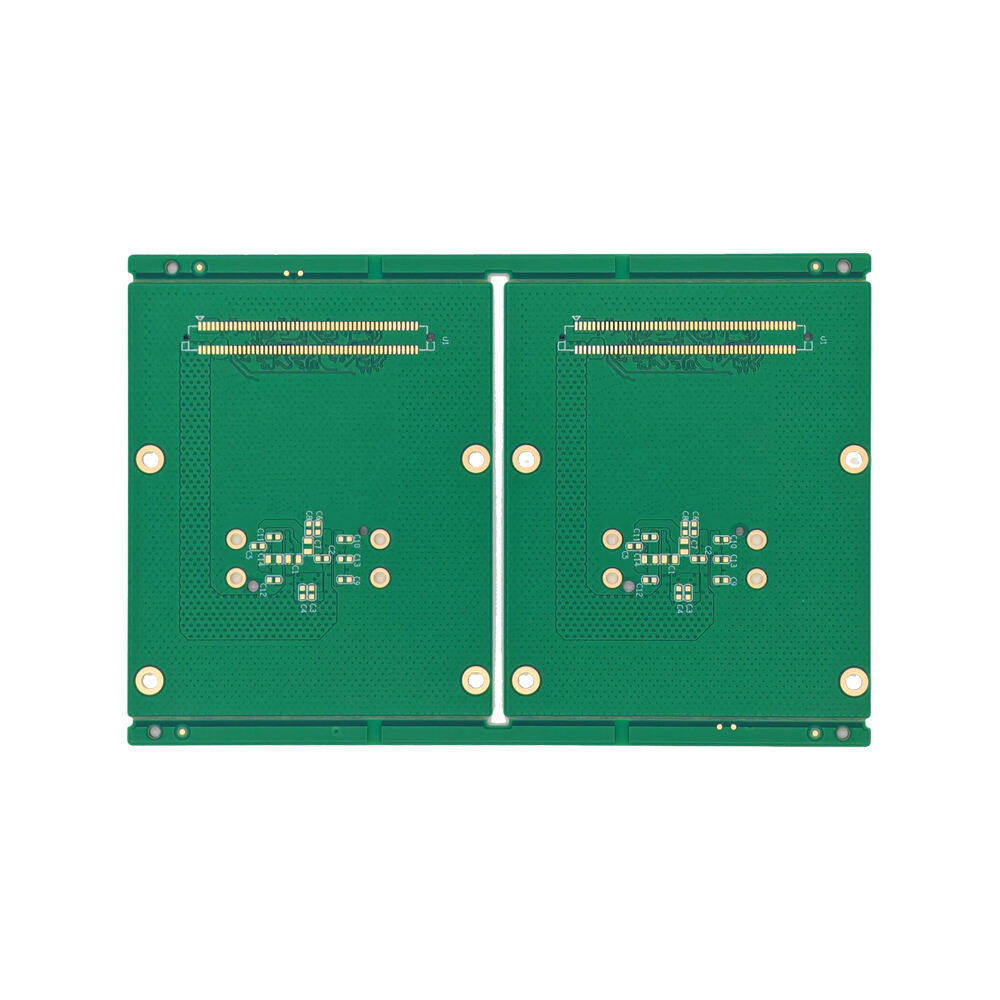

Beyond customized assembly services, several manufacturers provide comprehensive PCB solutions, focusing on detailed Gerber electronic circuit board production. These services excel with their ability to adapt to diverse manufacturing needs, from single-sided to complex multilayer circuit boards. Their environmental guidelines and rigorous quality checks build a strong foundation for enhancing customer trust through verified high-quality outcomes.

Controller prototype circuit board assembly custom services play a pivotal role in the development phase of PCB manufacturing, allowing companies to refine and iterate designs before mass production. Utilizing advanced testing systems, these services offer robust quality control measures, ensuring that every prototype aligns with the highest industry standards—serving as an invaluable tool in developing reliable electronic products.

The future of PCB design is brimming with exciting advancements like IoT integrations and the rise of flexible PCBs. As technology evolves, these trends are becoming pivotal, pushing designers to create PCBs that can seamlessly integrate with smart devices and adaptable technologies. The growing demand for IoT devices is leading to more compact and efficient designs, while flexible PCBs enable more innovative applications in constrained spaces. To tackle future challenges, continuous learning and improvement within the PCB design community are essential. As technology rapidly advances, staying updated with the latest techniques and methodologies is crucial for maintaining competitive advantage and enhancing design efficiency. By fostering a culture of learning, designers can better adapt to new developments, ensuring robust and future-ready PCB designs.