Custom circuit boards play a pivotal role in modern electronics by offering tailored solutions that enhance device performance and efficiency. These boards are meticulously designed to suit specific applications, whether it involves complex signal processing, precise power distribution, or other specialized functions. By incorporating customized PCB assembly methods and materials, manufacturers can ensure that each board meets unique operational requirements, thereby optimizing the functionality of electronic devices.

In sectors like telecommunications and healthcare, the demand for custom circuit boards is rapidly increasing. A report by Market Insights indicates that the global market for customized PCBs is expected to grow significantly, driven by technological advancements and the need for reliable, high-performance components in critical applications. Tailoring circuit solutions allows these industries to address specific challenges, ensuring that devices perform consistently even under demanding conditions.

The importance of custom circuit boards is further underscored by their ability to provide bespoke solutions for industry-specific needs. Whether it's employing customized PCBA repair services or selecting PCB board power supplies, the tailored approach helps improve overall system performance and reliability. The ongoing growth in demand reflects the crucial role of custom PCBs in supporting the advancement of electronic technology across various sectors.

Designing custom circuit boards involves a detailed step-by-step process, crucial for developing reliable and efficient electronic products. The journey begins with conceptualization, where designers outline the board's purpose and requirements. This is followed by schematic design, which involves drafting a blueprint of the electronic circuit. The next step is layout design, where components are precisely placed on the board to ensure optimal functionality and signal integrity. Finally, the design is sent for production, where the board is manufactured using advanced techniques.

Several software tools are integral to PCB design, each offering unique features and benefits. Altium Designer is known for its robust schematic capture and PCB layout capabilities. Eagle, on the other hand, is favored for its user-friendly interface and extensive library of components. KiCAD, an open-source option, provides a comprehensive suite of tools for schematic capture, PCB layout, and 3D visualization. These tools streamline the design process, helping engineers create high-quality PCBs tailored to specific needs.

Prototyping and testing play a vital role in the design process, emphasizing iterative design and the importance of user feedback. Iterations allow designers to refine their work based on testing outcomes, leading to superior product performance. For instance, a case study on the development of a custom PCB for a healthcare device highlighted how iterative design and user insights significantly enhanced product reliability and efficiency. Through prototyping, teams can validate the functionality of a board before moving to mass production, thereby minimizing errors and supporting customized PCB assembly methods.

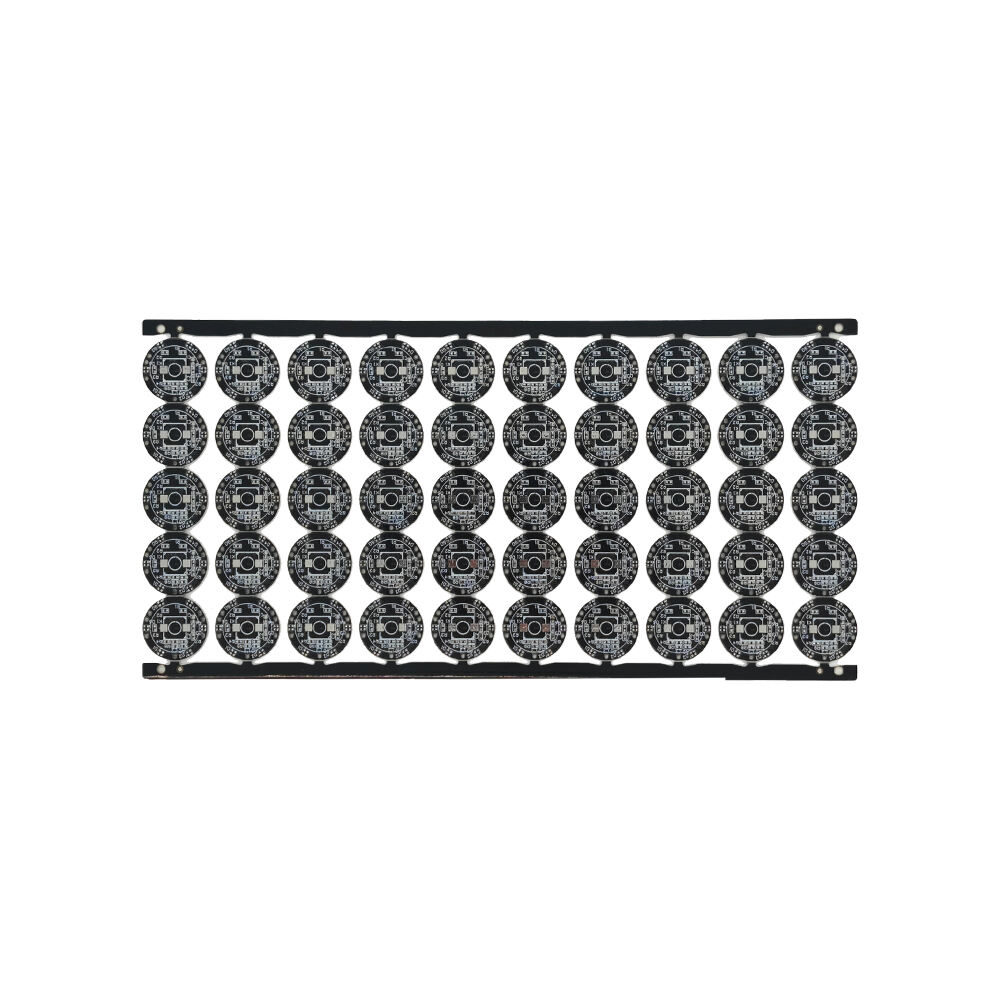

Custom circuit boards can be categorized based on complexity and application. Single-sided PCBs are the simplest form, with electronic components mounted on only one side. They are often used in low-density designs such as calculators and power supplies. In contrast, double-sided PCBs allow connections on both sides of the board, offering greater flexibility and are commonly used in consumer electronics, appliances, and LED lighting. These types vary in complexity, with double-sided boards being more intricate due to the presence of vias that connect components on both sides.

On the other hand, multilayer PCBs integrate multiple layers of circuits in a compact format. This design is prevalent in sophisticated devices such as smartphones and laptops, where space is premium. The additional layers allow for refined signal routing and improved thermal management. Flexible PCBs, made from materials like polyimide, offer the advantage of bending and folding without compromising functionality. This flexibility is especially advantageous in compact devices like wearable technology and medical equipment that require versatile space solutions.

In specialized industries, custom circuit boards are tailored for specific uses. Automotive boards must withstand harsh conditions and typically offer enhanced durability; they govern functions from navigation systems to engine controls. Aerospace applications often demand lightweight, high-performance boards capable of enduring extreme temperatures and vibrations. In consumer electronics, boards are optimized for miniaturization and enhanced connectivity, aligning with current trends for smaller, more powerful devices. According to industry data, the demand for multilayer PCBs in aerospace and automotive applications is projected to rise significantly, indicating a trend toward more complex PCB designs in these industries.

Custom circuit board solutions offer myriad advantages for optimizing electronic device performance and functionality. They are engineered to address specific requirements, enhancing efficiency and ensuring that devices function at their best. According to expert analysis, tailored PCBs contribute significantly to the operational improvement in various devices by minimizing electronic noise and improving thermal performance. This degree of customization allows for refined control over the device's performance parameters, enabling electronic devices to operate with optimal efficiency.

In addition to performance, the cost-effectiveness of custom circuit boards is apparent in the long term. Studies highlight that using bespoke PCBs results in reduced failure rates and lower maintenance costs over time. Although the initial cost of custom PCBs might be higher compared to off-the-shelf solutions, the savings from decreased need for repairs and replacements help recoup the initial investment. This aspect is crucial for businesses aiming to minimize lifecycle costs while ensuring high reliability in their electronic products.

Furthermore, custom circuit boards offer unparalleled design flexibility and customization, allowing for innovative and specific designs that standard PCBs cannot provide. Advances in technology have pushed the boundaries of PCB design, enabling the creation of complex geometries and the incorporation of novel materials and techniques. These advancements not only allow for unique, application-specific designs but also ensure adaptability to evolving technology and market demands. Whether it's customized PCBA repair services or tailored PCB assembly methods, this flexibility is a definitive advantage for companies seeking to innovate with precision.

The development of custom PCBs is fraught with challenges, primarily due to design complexity. This process often includes issues like signal interference and power distribution imbalances, which can complicate troubleshooting. To counter these, advanced design techniques such as differential signaling and precise grounding are employed. Additionally, design software aids in visualizing potential issues early, allowing for preemptive resolutions, thereby smoothing the development process.

Another significant hurdle in custom PCB production is addressing manufacturing limitations. Material constraints and technological capabilities can impede the development of printed circuit boards tailored to specific needs. Common constraints include minimum trace widths and drilling tolerances. To bridge the gap between design and manufacturability, strategies like Design for Manufacturability (DFM) are employed. This approach helps ensure the design aligns with production capabilities, fostering a seamless manufacturing flow.

Managing costs is pivotal in custom PCB projects. The scope of the project significantly impacts budgeting, as detailed in financial reports on PCB production. Costs must be balanced with desired functionality, often through strategic material use and collaborating with reliable suppliers. Techniques such as optimized component placement and minimal use of layers further enhance cost-effectiveness, ensuring project viability without compromising on performance or innovation.

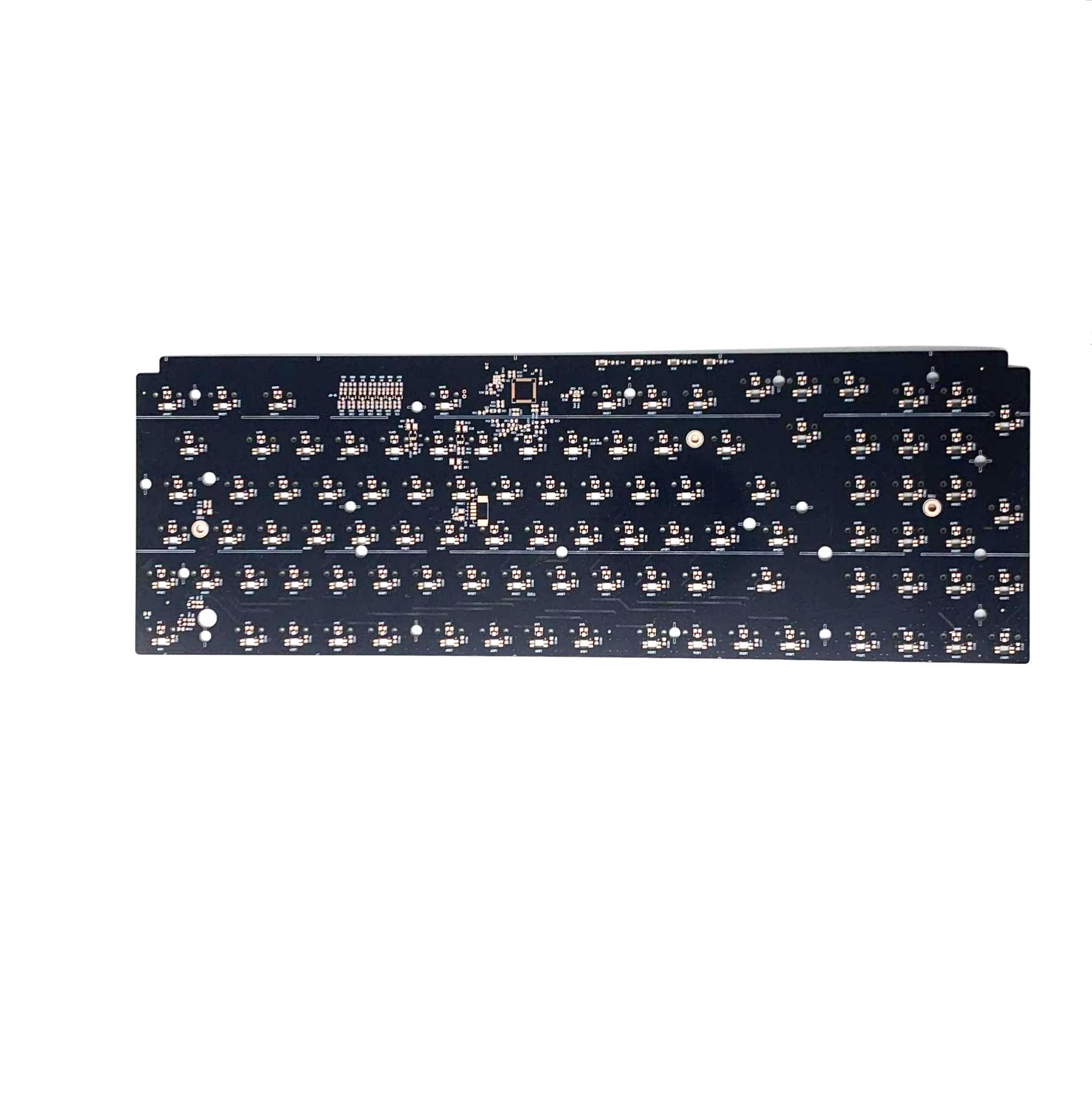

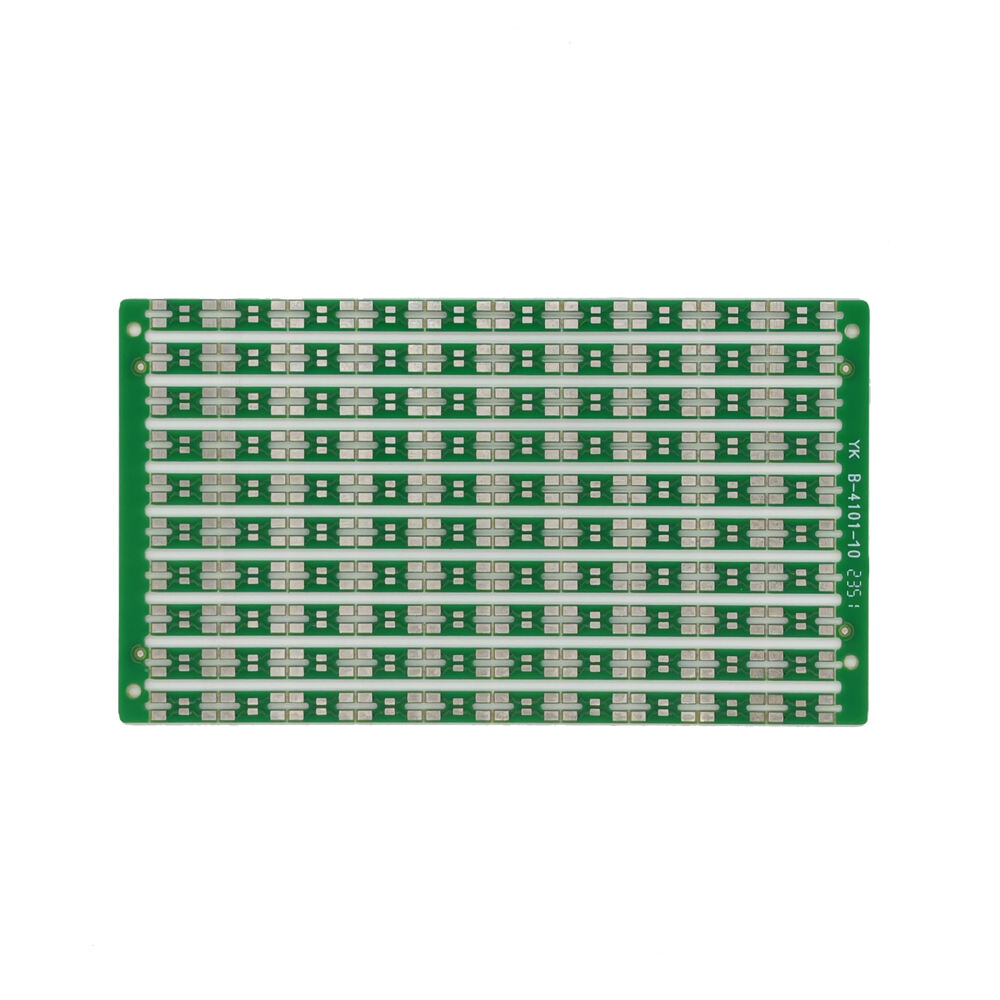

When it comes to highly sought-after custom circuit board products, the China Supply HDI Clone PCB Prototype stands out due to its unique features. This product supports single-sided, two-layered, multilayer, and high-density interconnector (HDI) PCBs, catering to industries like automotive, industrial lighting, and machinery. Renowned for its quality, it adheres to environmental guidelines, focusing on pollution prevention and resource conservation.

V0 Electronics Services is notable for its comprehensive approach to custom circuit design and manufacturing. With expertise spanning over a decade, they produce PCBs that support a range of industries, adhering to strict quality control tests like 100% E-test and AOI inspection, ensuring top-notch manufacturing capabilities.

The Double-sided HDI OEM PCB products offer significant fabrication potential. Ideal for collaboration with industry leaders, these circuit boards are engineered to serve high-demand environments like office appliances and electric toys, maintaining high standards with advanced quality assurance processes.