Custom PCBA offers unparalleled design flexibility, allowing for unique configurations tailored to specific electronic requirements. This adaptability is crucial for accommodating diverse component sizes and layouts, which enhances the versatility of electronic devices. By employing advanced design software, manufacturers can create intricate designs that meet the high-tech demands of modern applications like wearables and medical devices. For instance, these tools enable engineers to integrate specialized sensors into compact designs efficiently, ensuring optimal performance in restricted spaces.

Custom PCB manufacturing services provide significant cost advantages in both prototyping and mass production phases. Businesses often benefit from lower costs per unit due to economies of scale, making it a financially viable option. Prototyping with custom PCBA reduces research and development expenses, offering a more strategic approach to innovation. Industry reports suggest that companies can save up to 30% on costs by leveraging tailored PCB solutions, according to a 2023 study on PCB manufacturing trends. This efficiency in cost management is particularly important in competitive markets where budget constraints can impact product development timelines.

Speed is key in the dynamic world of electronics, and rapid turnaround times are essential for time-sensitive projects. Custom PCB manufacturers often provide expedited services, ensuring fast delivery and enabling companies to respond swiftly to market demands. Quick prototyping is a crucial advantage, allowing firms to reduce product development timelines and hit the market faster. Case studies highlight that businesses utilizing rapid PCB services have successfully reduced project timelines by over 20%, emphasizing the competitive edge that speed provides in the industry.

The journey to creating a fully functional PCB assembly at ShenChuang Precision begins with the transformation of Gerber files into manufacturable formats. This crucial initial step ensures that designs are accurately brought to life on the manufacturing floor. Seamless integration from design to assembly is key, fostering operational efficiency and reducing potential production errors. With expert technicians overseeing every facet of the conversion process, ShenChuang ensures that high-quality standards are maintained throughout, guaranteeing reliable and precise outcomes in functional PCB assemblies.

ShenChuang Precision excels in providing tailored ODM (Original Design Manufacturing) and OEM (Original Equipment Manufacturing) services to address the specific needs of various industries. This flexibility allows the company to offer custom configurations and rapid modifications, critical for staying competitive in ever-evolving markets. Client testimonials frequently highlight the effectiveness of these solutions, affirming their success across different sectors. By catering to a broad range of industry requirements, ShenChuang ensures that each project aligns specifically with the unique demands of its clients.

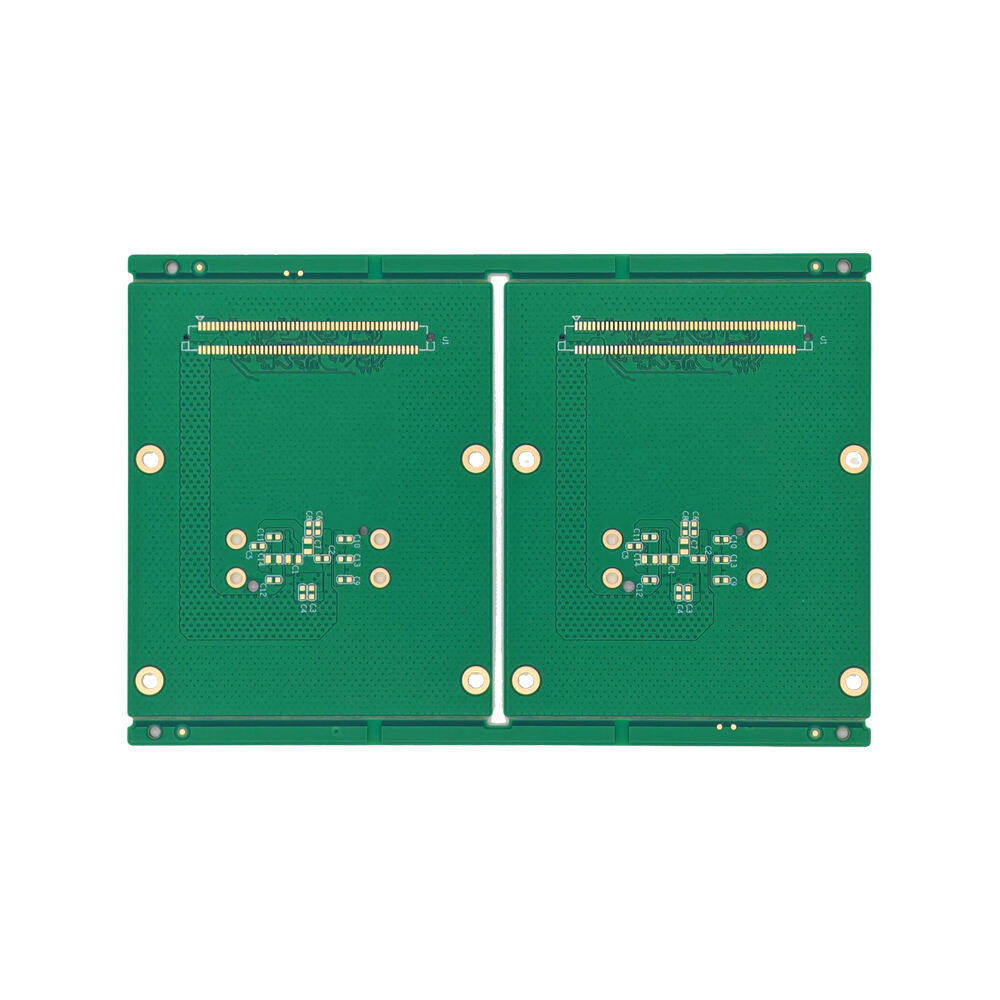

ShenChuang Precision's expertise in manufacturing multi-layer and High-Density Interconnection (HDI) PCBs enables the creation of compact and efficient circuit designs. Utilizing advanced manufacturing techniques, these PCBs offer enhanced performance and reliability, crucial for modern, complex devices. Statistics indicate that HDI PCBs can improve functionality in devices by up to 40%, underscoring the significant advantages they provide. Through continuous innovation and precision, ShenChuang demonstrates its capability to meet the stringent demands of today's technology landscape effectively.

Adhering to internationally recognized standards like ISO and RoHS is crucial for quality assurance in PCB manufacturing and assembly. These certifications demonstrate compliance with global quality and safety guidelines, ensuring the longevity and reliability of printed circuit boards. Regular audits and evaluations help manufacturers maintain compliance with these standards and continuously enhance their processes. This rigorous approach not only assures clients of product safety but also supports the sustainability efforts by minimizing hazardous substances in the manufacturing process.

Automated Optical Inspection (AOI) is a pivotal technology in PCB manufacturing, as it swiftly and accurately identifies defects, thereby minimizing errors. Statistical data suggests that AOI can reduce inspection time by approximately 60%, a significant saving in manufacturing operations. Rigorous reliability testing further ensures that the PCBs perform efficiently under various conditions. This combination of AOI and reliability testing assures customers that their products are built to withstand diverse environmental stresses, enhancing overall satisfaction and trust in the product.

Effective thermal management and signal integrity optimization are key design considerations that enhance PCB performance. Efficient heat dissipation strategies are vital for the longevity of the printed circuit board, as they prevent overheating issues. Simultaneously, optimizing signal integrity is crucial for overall performance, ensuring that the signals within the board are transmitted without loss. Expert evaluations indicate that optimized layouts can prevent up to 85% of signal loss issues. Thus, these strategies are fundamental to ensuring the reliability and efficacy of PCB assemblies.

Custom Printed Circuit Board Assembly (PCBA) is integral to the advancement of automotive electronics and industrial control systems. It enhances vehicle safety and performance by supporting features such as advanced driver-assistance systems. In industrial settings, precise PCB designs enable effective automation and control, boosting efficiency and reliability. Market trends, backed by research, project a 10% growth rate in automotive electronics by 2025. This underscores the rising demand for sophisticated PCBA solutions to support this evolving industry landscape.

Medical devices and high-precision instrumentation rely heavily on custom PCBA for their functionality and accuracy. These life-critical devices demand stringent quality standards in production to ensure reliability and safety during operation. PCBA solutions provide the reliability necessary for accurate medical diagnostics and treatments. The steady increase in demand for precision instrumentation is supported by research indicating its crucial role in advancements in healthcare technology. Consequently, the medical sector is witnessing substantial growth, fueled by innovations in PCBA design and manufacturing.

The rapidly evolving Internet of Things (IoT) sector depends on custom PCBA for the functionality of devices and infrastructure. Efficient PCB designs are essential for smart energy applications, enabling energy conservation and optimized power consumption. Forecasts predict a doubling of IoT devices by 2030, emphasizing the need for advanced PCB solutions. As smart energy applications become more prevalent, PCBA innovations will continue to fuel growth in the IoT industry, paving the way for more connected and sustainable solutions.

ShenChuang Precision emphasizes delivering top-notch quick-turn PCB board assembly services to meet the industry's urgent demands. By focusing on quick turnaround times without compromising quality, they cater to clients with time-sensitive projects, ensuring a competitive edge in the fast-paced market of PCB manufacturing. Client testimonials often praise their ability to balance speed with precision, highlighting a consistent track record of satisfaction with the outcomes.

ShenChuang Precision provides comprehensive PCBA manufacturing services, from sourcing components to final assembly, with robust BOM and Gerber file support. This integrated approach ensures smoother project completion and reduces production delays, ultimately optimizing the entire manufacturing lifecycle. Evidence suggests that companies using these services experience fewer disruptions, confirming the effectiveness of ShenChuang's structured process solutions.

ShenChuang's specialized services in prototype development for controller circuit boards accelerate the time to market for new technologies. Their rapid prototyping capabilities allow businesses to iterate quickly, facilitating a higher success rate for innovative products. Statistics reveal that utilizing effective prototypes dramatically boosts product launch success, and ShenChuang’s services are tailored to support these outcomes with precision and expertise.