The roll-out of 5G networks is significantly boosting the demand for printed circuit boards (PCBs). Market reports anticipate growth rates exceeding 15% in sectors related to 5G infrastructure and devices, primarily because this technology supports faster data transmission and greater connectivity. As 5G becomes more widespread, industries such as telecommunications and consumer electronics are likely to experience an increase in PCB demand to meet these needs.

Further amplifying the demand for PCBs is the proliferation of the Internet of Things (IoT). By 2030, forecasts suggest that over 50 billion devices will be connected worldwide, driving a substantial need for robust PCB solutions. IoT devices, which require seamless connectivity and data exchange, will depend heavily on advanced PCBs for efficient operation and communication.

The technological requirements for IoT devices further emphasize miniaturization and complexity. These requirements create a significant demand for advanced PCBs capable of supporting small, intricate circuits. PCB manufacturers are focusing on innovations that can cater to these needs, integrating features like multiple layers and high-density interconnects.

Sustainable manufacturing practices are increasingly influencing PCB production processes. Companies worldwide are committing to reduce carbon footprints and minimize waste, partially driven by rising consumer awareness and environmental regulations. Recent surveys indicate a significant shift towards more sustainable practices in the industry, as manufacturers integrate eco-friendly processes.

One of the key developments in this shift is the adoption of advanced, eco-friendly materials and methodologies in PCB fabrication. This includes the use of biodegradable substrates and low-impact manufacturing processes that reduce harmful emissions. As sustainability becomes a major focus, manufacturers are investing in innovative materials and processes to remain competitive and compliant with environmental standards.

Regulatory bodies are also playing a critical role in promoting sustainable practices in PCB manufacturing. Certifications, such as those provided by ISO, establish standards that guide companies toward more environmentally responsible production methods. These regulations are crucial in ensuring that manufacturers adhere to best practices in sustainability, further reinforcing the industry's shift toward eco-friendly operations.

The Asia-Pacific region continues to dominate the global PCB market, with significant growth projected in the coming years. This region's market share is supported by its established electronics manufacturing industry and robust infrastructure, contributing significantly to global trade. Statistics highlight the region's influential role, with countries like China and Taiwan spearheading growth.

China and Taiwan are key players in the electronics manufacturing landscape, benefiting from strong government support initiatives that bolster industry development. Government-led programs in these countries often focus on enhancing technological capabilities and providing financial incentives to support manufacturing processes, further strengthening their positions in the global market.

Moreover, the labor cost advantages and advanced technological infrastructure in the Asia-Pacific region solidify its dominant status. Competitive labor costs allow manufacturers to maintain lower production expenses, while the region's advanced technological capabilities support the production of sophisticated PCBs. This combination of factors ensures that the Asia-Pacific region remains a powerhouse in PCB manufacturing and continues to drive industry expansion globally.

ShenChuang Precision has strategically positioned itself to harness the capabilities of Shenzhen's robust electronics supply chain network. This connectivity allows the company to offer rapid prototyping and slashed time-to-market, which is crucial in the fast-paced world of printed circuit board (PCB) manufacturing. The efficiencies in logistics within this network significantly reduce costs and improve delivery times, making ShenChuang Precision a competitive player in the market. By forming partnerships with local suppliers and manufacturers, ShenChuang gains access to cost-effective solutions and innovative technologies essential for creating state-of-the-art PCBs.

These collaborations have enabled ShenChuang to maintain a high standard of quality in their products, capitalizing on the local supply chain's strengths. Such synergies enhance their ability to keep up with industry demands, presenting a competitive advantage over firms in less integrated regions. This strategic connection not only boosts product quality but also fortifies ShenChuang's market position in a highly competitive industry.

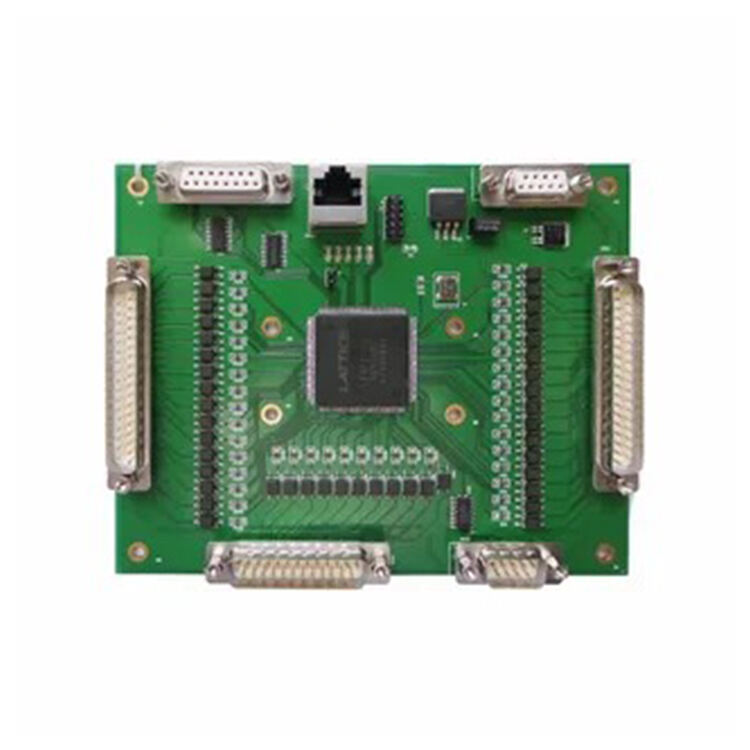

The global PCB market significantly relies on Original Design Manufacturer (ODM) and Original Equipment Manufacturer (OEM) services, where ShenChuang Precision has demonstrated notable expertise. Their cutting-edge capabilities in multilayer PCB fabrication cater to a growing demand, as industry forecasts predict the multilayer PCB sector to experience a compound annual growth rate of 5.6% from 2024 to 2029. ShenChuang's market offerings in this space reflect their commitment to pioneering advancements and meeting market expectations with precision.

Integrating this expertise, ShenChuang has successfully delivered numerous projects showcasing their proficiency in producing multilayer PCBs. Each case highlights their ability to handle complex designs and meet stringent quality standards, reinforcing their reputation as a reliable partner in multilayer PCB technologies. This specialization not only contributes to their growth but also positions them as leaders in the evolving landscape of printed circuit board assembly.

For ShenChuang Precision, securing certifications like ISO and IPC standards is vital to accessing global markets for their PCB manufacturing services. These certifications validate the company's adherence to international standards, bolstering product reliability and customer trust. Achieving such compliance is critical, as it aligns ShenChuang with industry expectations and enhances their products’ marketability.

Customer feedback consistently reflects the reliability and quality of ShenChuang's offerings, underscoring the importance of compliance. ShenChuang’s commitment to high standards and continuous improvement exemplifies their dedication to excellence in printed circuit board manufacturing. By maintaining rigorous compliance, ShenChuang not only satisfies global market demands but also ensures sustained competitive advantage and operational excellence in the industry.

High-quality multilayer PCB manufacturing is a complex process requiring advanced technology and machinery to ensure high precision and reliability. ShenChuang employs cutting-edge equipment and methodologies to produce multilayer PCBs that meet rigorous international standards. This includes techniques such as using high-density interconnect (HDI) strategies and utilizing substrate-like PCB technology, enabling enhanced thermal management and signal integrity. Quality assurance is paramount, with ShenChuang implementing thorough testing protocols like 100% E-tests and AOI inspections to maintain consistent quality. As a result, customer satisfaction remains high, as evidenced by numerous successful partnerships that underscore ShenChuang's commitment to excellence in PCB manufacturing.

End-to-end PCBA assembly with Gerber and BOM integration is crucial in reducing errors and enhancing the efficiency of electronic production processes. ShenChuang expertly integrates these files, resulting in streamlined workflows and minimized discrepancies, ultimately boosting productivity and collaboration with partners. This seamless integration serves as a backbone to ShenChuang's assembly process, ensuring precise component placement and a reduction in lead times. By implementing such methodologies, ShenChuang has successfully completed numerous PCBA projects, demonstrating enhanced efficiency and reliability, which continually attract significant partnerships and customer satisfaction metrics.

Offering one-stop electronic component sourcing and assembly optimizes clients' supply chains and simplifies logistics, translating into significant time and cost savings. ShenChuang has cultivated strategic supplier relationships, enabling a diverse range of components and fostering seamless integration within assembly processes. The industry trend towards single-source supply solutions evidences a growing preference among OEMs and ODMs for streamlined operations, and ShenChuang's offerings meet these demands. Market analysis suggests a shift towards these comprehensive services, where efficiency and reliability are paramount, boosting ShenChuang's competitive edge and client satisfaction.

The PCB manufacturing industry faces significant challenges due to the complexities of global supply chains, especially in the wake of the pandemic. Logistic issues, material shortages, and fluctuating costs have disrupted production and impacted businesses economically. According to industry reports, the global PCB market, valued at $67.9 billion in 2023, has seen supply chain disruptions as a critical growth barrier. Companies like ShenChuang are tackling these issues by adopting robust risk mitigation strategies, such as diversifying supplier networks and implementing advanced inventory management systems. Recent industry analyses indicate potential recovery pathways, emphasizing enhanced logistics infrastructure and strategic stockpiling to bolster supply chain resilience.

High-Density Interconnect (HDI) and flexible PCBs are at the forefront of innovation in the electronics industry, with market forecasts predicting a CAGR of 6.4% for HDI PCBs from 2024 to 2029. These advanced PCBs are crucial for compact and high-performance electronic devices. Technological advancements and R&D are pivotal in driving innovation, with companies like ShenChuang investing in cutting-edge projects to enhance these products. Industry experts foresee a bright future for HDI and flexible PCBs, driven by increased demand in applications ranging from consumer electronics to automotive sectors. This focus on next-generation PCBs positions manufacturers to meet evolving technological needs and tap into emerging markets.

Adopting a circular economy model in PCB production is essential for sustainability and reducing electronic waste. The circular economy emphasizes recycling and sustainable production practices to minimize waste and resource consumption. ShenChuang has embraced initiatives such as closed-loop recycling and eco-friendly materials to promote sustainability. Factual data from industry reports reveal significant benefits from these practices, including cost savings and reduced environmental impact. As the market shifts towards eco-friendly solutions, implementing circular economy principles is becoming a competitive advantage for PCB manufacturers keen on future-proofing their operations and aligning with global sustainability trends.