PCB (Printed Circuit Board) design is an essential step in the development of electronic products. A well-designed PCB ensures reliable performance, proper connectivity, and efficient signal transmission in electronic devices. SHEN CHUANG, a leader in PCB design and manufacturing, provides cutting-edge solutions to meet the growing demands of modern electronics. Here are the basic requirements and processes of PCB design.

Understanding the Basic Requirements

The first step in PCB design is to understand the specific requirements of the project. This includes selecting the right materials, determining the size of the board, and ensuring that the design accommodates all components, such as resistors, capacitors, and integrated circuits. SHEN CHUANG helps engineers navigate these challenges, offering high-quality materials and advanced design tools to meet the unique needs of each project.

Schematic Design and Component Placement

Once the basic requirements are understood, the next step is schematic design, where all the electronic components and their connections are mapped out. This blueprint forms the foundation for the PCB layout. Afterward, the components are placed on the PCB in an optimized manner to minimize interference and ensure proper signal flow. SHEN CHUANG provides professional design services that ensure component placement is both efficient and practical.

PCB Layout and Routing

In the PCB layout phase, the electrical connections between components are created using copper traces, vias, and pads. The routing of these traces is critical to minimizing signal loss and avoiding short circuits. Proper spacing and layer stacking are also essential for maintaining board integrity. SHEN CHUANG's design tools and expertise help engineers achieve high-performance layouts while adhering to industry standards.

Design Validation and Testing

After the PCB layout is complete, it undergoes design validation and testing. This phase ensures that the board functions correctly and meets all electrical and mechanical requirements. Tools like Design Rule Check (DRC) and Electrical Rule Check (ERC) are used to identify potential errors before manufacturing. SHEN CHUANG offers robust testing and validation services to ensure the final product meets the highest quality standards.

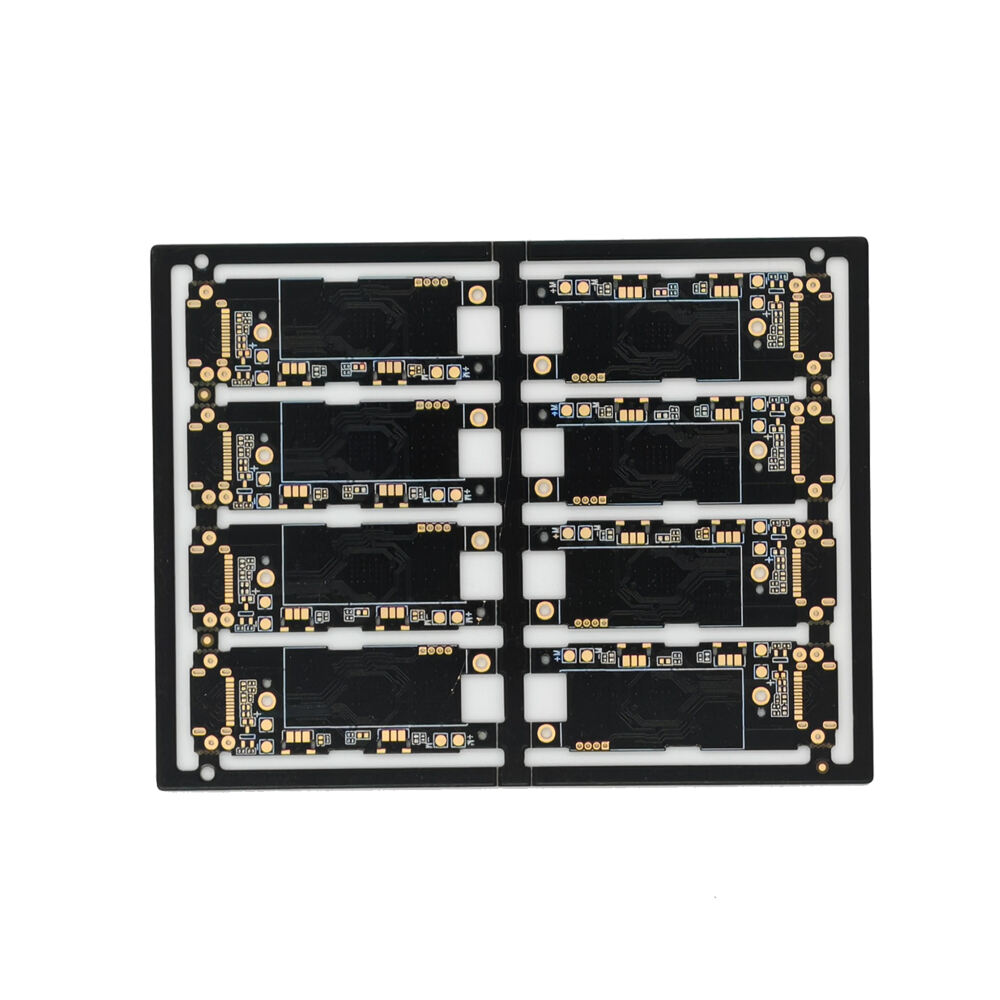

Manufacturing and Assembly

Once the design is validated, the PCB moves to the manufacturing stage. This involves creating the board, placing components, and soldering them in place. SHEN CHUANG offers efficient PCB manufacturing and assembly services, ensuring that each board is produced with precision and reliability.

PCB design is a multi-step process that requires careful attention to detail and the use of advanced tools and materials. With the expertise of SHEN CHUANG, engineers can create high-quality, efficient PCBs that meet the needs of modern electronics. By following the basic requirements and processes, from schematic design to manufacturing, you can ensure a reliable and functional final product.