FR-4 is a composite material consisting of woven fiberglass cloth and epoxy resin, extensively used in the fabrication of printed circuit boards (PCB) due to its excellent insulating properties. The fiberglass cloth contributes to the material's mechanical strength and dimensional stability, while the epoxy resin acts as a binder, forming a rigid layer that can support copper traces crucial for circuit functionality. This composite structure enables manufacturers to create reliable and efficient PCBs at a lower cost, making it a go-to option for a wide range of electronic applications, from consumer electronics to industrial control systems.

Additionally, FR-4 is distinguished by its flame retardant properties, with the 'FR' in 'FR-4' representing 'Flame Retardant'. This feature is critical in ensuring safety standards are met across various applications, as it helps prevent fire hazards by delaying the spread of flames. This capability makes FR-4 suitable for use in many environments, including those requiring stringent safety measures. Consequently, the combination of cost-effectiveness, structural robustness, and safety attributes ensures FR-4's prominence in the global PCB manufacturing industry.

The reliability of PCB manufacturing is vital because it influences the lifespan and performance of electronic devices, with FR-4 substrates playing a crucial role. As a staple in the printed circuit board manufacturing process, FR-4 substrates are favored for their consistent performance in various applications, from consumer electronics to industrial equipment. This material is essential in ensuring that electronic devices operate effectively over time without unexpected failures due to substrate inconsistencies. Thus, the significance of FR-4 substrates in manufacturing processes can hardly be overstated, as they are integral to producing durable and dependable electronic assemblies.

Performance characteristics of FR-4 substrates further enhance their suitability for high-performance applications. With a low dielectric constant, typically ranging between 4.2 to 4.6, FR-4 substrates minimize signal loss during high-frequency operations. This feature is particularly important in applications where signal integrity and optimal functioning of the final product are paramount. The low dielectric constant allows for the construction of circuits with minimal interference and energy loss, crucial for maintaining the precision and accuracy required in advanced electronic assemblies. Consequently, these unique properties of FR-4 make it an indispensable component in ensuring the high performance of modern PCB assemblies.

FR-4 PCBs have become integral to consumer electronics, facilitating compact designs and efficient heat management. In devices like smartphones and tablets, FR-4 substrates allow for the creation of sleek profiles without compromising on performance. Their low moisture absorption and durability make them ideal for devices that are frequently handled and require consistent performance in various environments.

In the automotive industry, FR-4 substrates are favored for their robustness and reliability. They are commonly used in engine control units and infotainment systems, where they must withstand extreme temperature fluctuations and vibrations. These characteristics ensure the durability and effective performance of automotive components critical to vehicle safety and user experience.

Industrial control systems also benefit significantly from the reliability of FR-4 PCBs. The need for continuous operation and the ability to manage high-power applications make FR-4 substrates an optimal choice. Their ability to maintain integrity and functionality in rigorous settings is crucial for industries where downtimes are costly and operational consistency is paramount.

Through these diverse applications, FR-4 PCBs demonstrate their versatility and importance across various sectors by combining affordable printed circuit board manufacturing with robust performance characteristics.

FR-4 materials encounter significant challenges in high-frequency applications, as their performance tends to degrade due to various loss factors that impact signal integrity. This material is not ideal for high-frequency electronics because it cannot maintain the dielectric constant necessary for stable signal transmission. For instance, FR-4 has a dissipation factor (Df) of around 0.020, which is considerably higher than that of most high-frequency laminates, typically around 0.004. Consequently, FR-4 materials are prone to signal losses, making them less suitable for applications requiring precise signal integrity in high-frequency environments.

Another notable limitation of FR-4 substrates is their environmental sensitivity, particularly to moisture and temperature fluctuations, which can compromise both reliability and performance. While FR-4 shows moderate moisture resistance, exposure to higher temperatures can diminish its mechanical and electrical properties. The inability to withstand constant high temperatures without deteriorating around 130°C makes them unsuitable for specific high-temperature environments. Therefore, engineers must consider these constraints when selecting materials for printed circuit board manufacturing, ensuring that FR-4 is the appropriate choice for the application at hand, or opt for alternative materials when necessary.

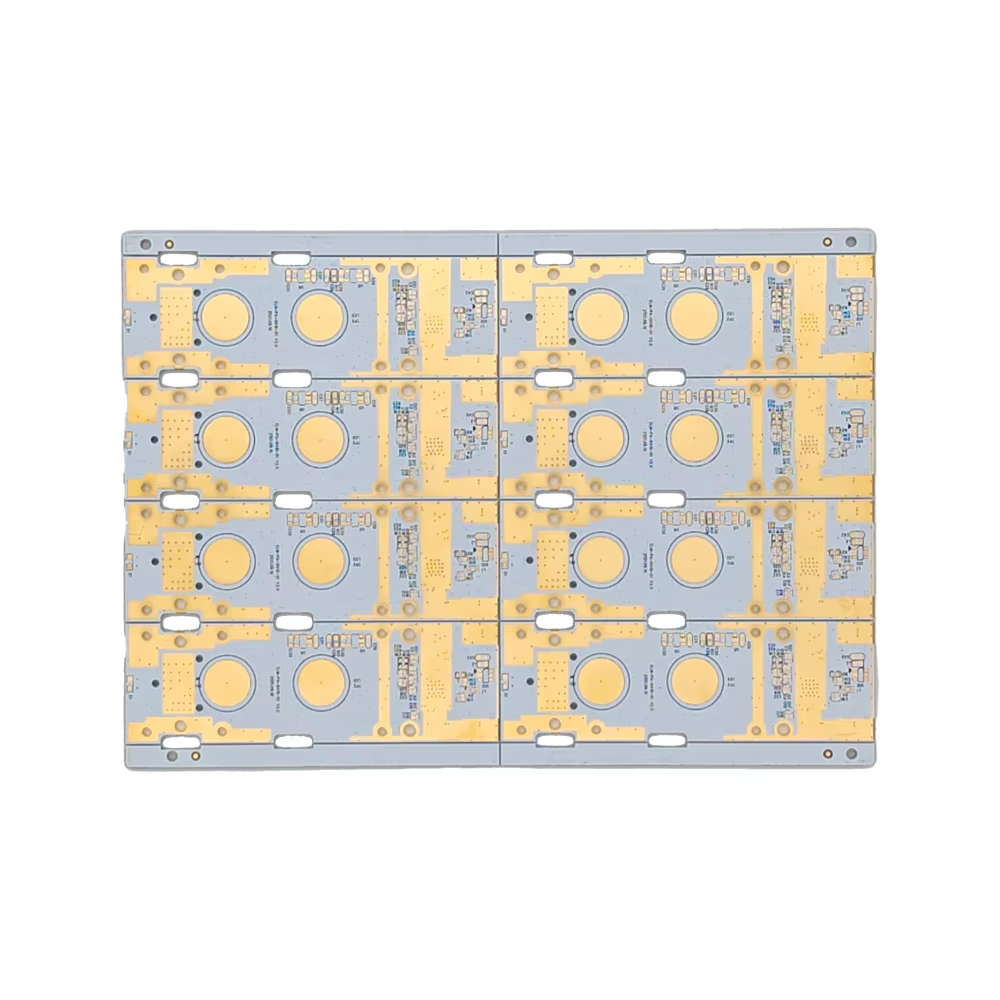

Several innovative products demonstrate the versatility and scalability of the FR-4 substrate in printed circuit board (PCB) manufacturing. The Pcb Board Assembly printing Top Quality Customized Quick Turn PCB Circuit Board PCBA Assembly showcases how FR-4 can be utilized effectively in bespoke electronic applications. This product benefits from the durability and flame-retardant properties of the FR-4 material, making it a suitable choice for various industry applications, including automotive and industrial lighting.

The OEM Multilayer PCB Circuit Board Photosensitive Dry Film PCB Board Assembly Circuit Board illustrates the scalability of FR-4 in supporting complex designs and manufacturing processes. This product capitalizes on the material's excellent electrical and thermal properties, which are essential for producing high-density multilayer PCB designs.

Lastly, products like other PCB need gerber electronic circuit board manufacturing factories processing PCB reflect on the collaborations with manufacturing factories to exploit FR-4's benefits fully. These collaborations ensure that the expansive applications of FR-4 substrates are effectively utilized in crafting complex printed circuit board assemblies.