As far as the electronics industry is concerned, it is advancing rapidly that the only way of addressing the technology needs is through provision of customized solutions. Among the most intriguing companies in the electronic business of course is the SHEN CHUANG, which offers world class tailor made PCBA service for sophisticated electronic applications. Whenever working on the designs of highly innovative consumer electronic products or ruggedized equipment, the PCBA solutions offered by SHEN CHUANG assures of the accuracy, quality and reliability that enables the smooth functioning.

What makes SHEN CHUANG unique is its extra level of care and attention in the design, as well as the manufacture of the products. The firm provides a comprehensive range of custom PCBA services that covers design, prototyping and volume production. These include but are not limited to the telecommunications, medical devices, automotive electronics, and many more. By engaging in such a process, she is able to ensure that every PCBA produced is appropriately executed in term of the project requirements which includes size impact, placement of components, signal loss and other heat strategies employed.

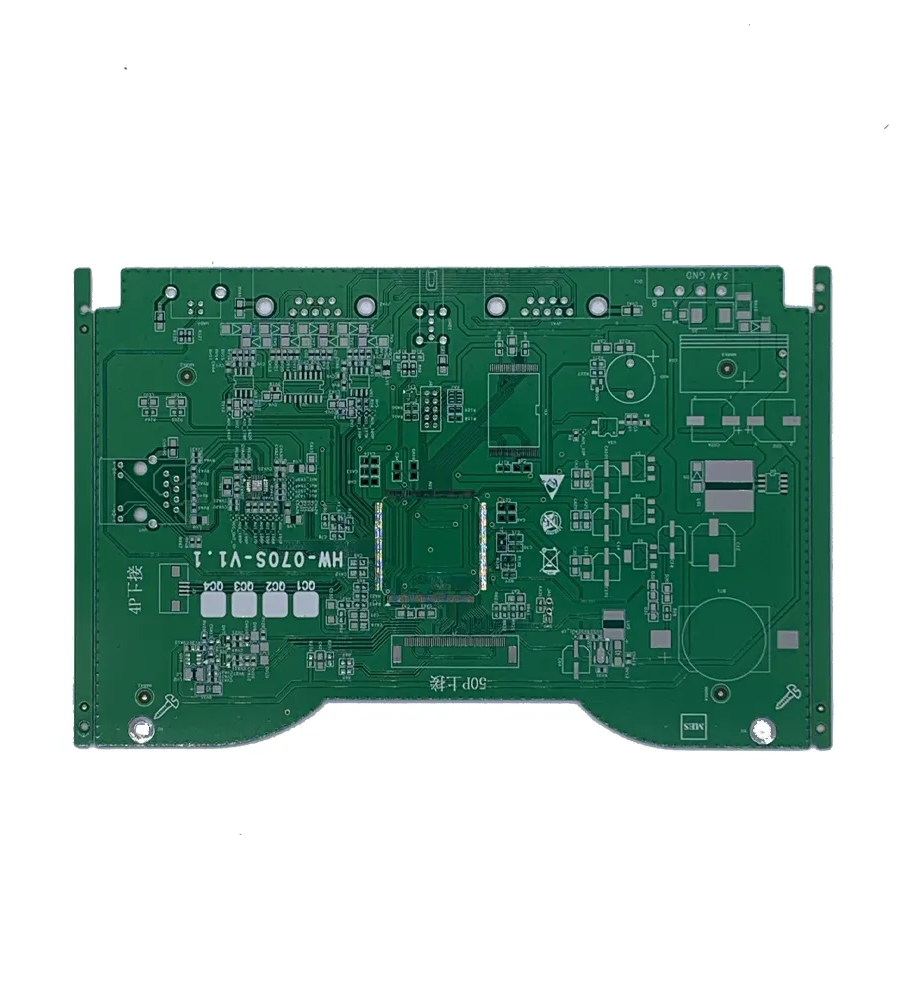

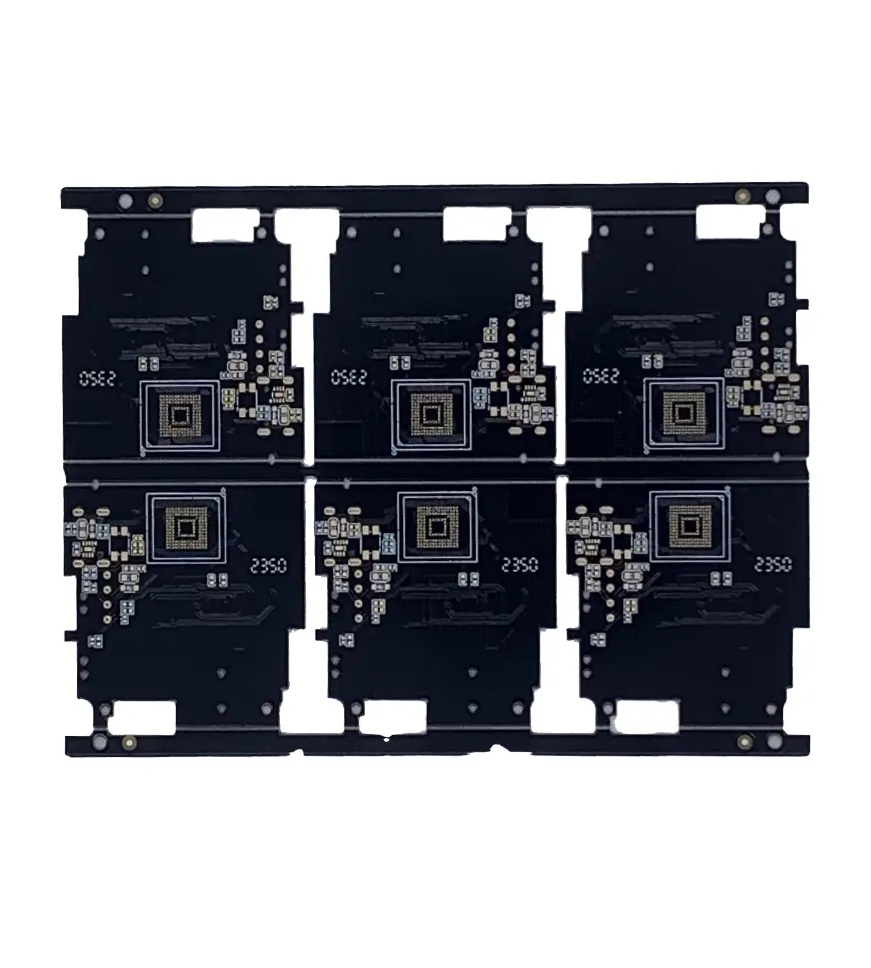

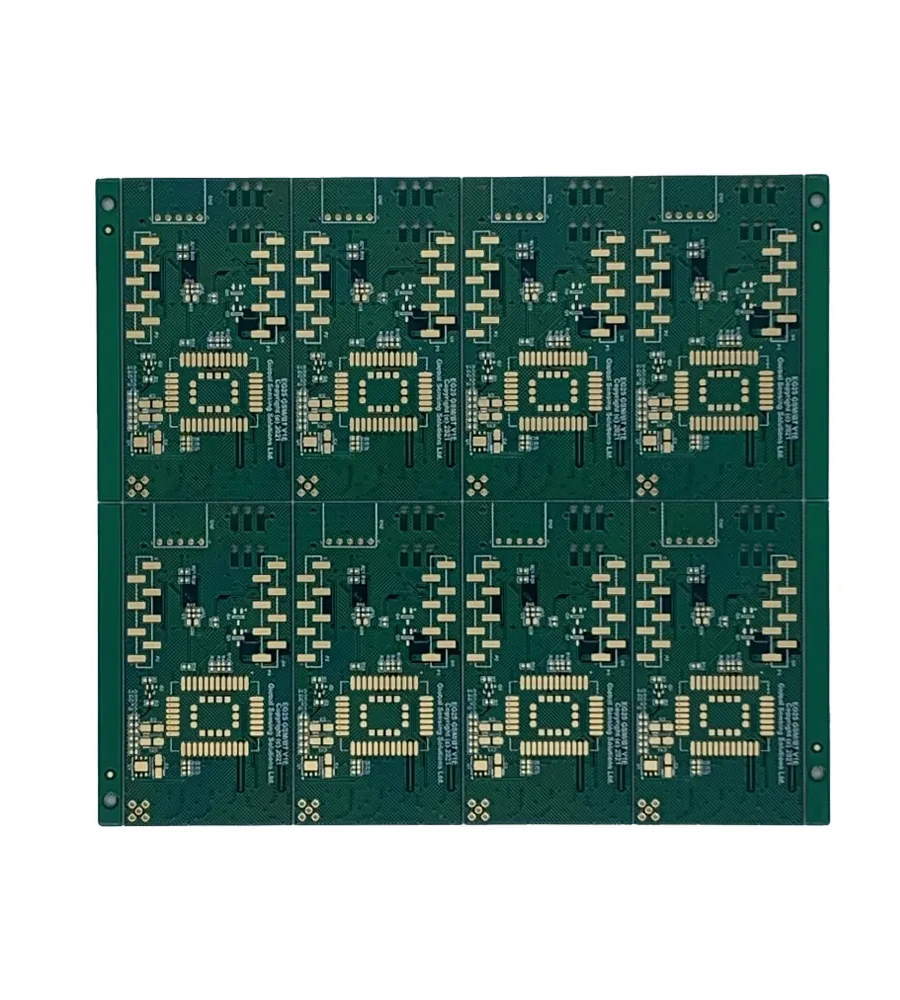

SHEN CHUANG's customized PCBA adheres to the highest industry standards and is produced with the latest equipment. There is a rigorous board test for each board made to determine their ability to perform in the most extreme conditions. The usage of good quality materials in conjunction with modern day manufacturing technology guarantees that the end product does not only satisfy the world’s expectations but also surpasses them.

Custom PCBA solution from SHEN CHUANG will give businesses in a competitive situation the extra edge that is hard to come by. Prototypes in small or large quantities are no problem with SHEN CHUANG as the company has what it takes in terms of putting together resources to provide input that positively affects the end product.

The bottom line is that SHEN CHUANG appreciate that their customers demand a response that is innovative and fast, thus the clients tend to appreciate the company’s innovative nature and expertise in PCBA services. Because of its emphasis on high quality and customer service, SHEN CHUANG is being able to sustain the progress of PCB assembly technology so that every custom made application meets its purpose.

At SHEN CHUANG, to say quality is a promise is an understatement; it is simply over and above. C usto mized PCBA, as well as other products of the company, is subjected to complex processes and strict quality assurance procedures in every step of the production process. Each and every customized PCBA of the custom design and manufacturing process also goes several tests from the material selection to the final assembly to check the performance parameters and safety standards. X_ ray or automated optical inspection or environmental stress testing is employed by SHEN CHUANG for your customized PCBA working effectively under any circumstances. Such quality is earned through the global reputation that SHEN CHUANG enjoys under the supply of electronic assemblies on demand to its clients. With SHEN CHUANG, you can rest assured that the PCBA received is proven, qualified, and guaranteed for high performance.

At SHEN CHUANG, we understand that nothing gives customers more satisfaction than seamless precision engineering, and this is the core of our activities towards customization of PCBA services. Each PCBA made in our advanced manufacturing facilities, supported by our engineers, is a result of thoughtful creativity and impeccable assembly that dwells on your specifications. From consumer electronics to automotive systems and even medical devices, SHEN CHUANG has all the expertise to offer you customized PCBA’s for your needs. Recognizing that no project is the same; we offer services that encompass the entire cycle from custom design and prototyping, to the end of the line manufacturing. Thanks to SMT and TH assembly technologies, SHEN CHUANG makes certain that every Custom-made PCB assembly is as good as its design so that no malfunction is experienced in the field. Quality control being an essential part in the flow of production and assembly are in such a way that finished products positively impress every customer about the needs for SHEN CHUANG as a high-end electronics manufacturer.

With a proven track record of operating in different geographical regions and in a variety of industries, SHEN CHUANG has also acquired all the necessary skills and knowledge to successfully deliver tailored designed PCBA solutions to various market. Our enhancements in industrial technology also aid in capturing the latest trends in the market and construction of PCBAs suited for automotive, medical, telecommunications and renewable energy sectors. An even greater strength of SHEN CHUANG is our capability to create and fabricate PCBAs that meet applicable regulations, standards and certification because we have deep knowledge of the industries. For many companies, we are their only source of unique, efficient, and cost-effective PCBA structural modifications that unleash the innovative potential of their products. By obtaining the projected PCBA in compliance with the SHEN CHUANG strategy you will not simply meet the requirements of your target market hence ensuring the success and survival of your product in the current fast changing technology market.

Within the segment of focusing on customized PCBA manufacturing, SHEN CHUANG strives to satisfy each customer and every sector of the economy. It is our greatest achievement to collaborate with clients so as to gather their needs and create a unique, high-quality PCBA that meets their expectations. Thus, from the first design consultation till the last assembly, SHEN CHUANG is ready to provide a service package that develops your product in regard to its performance, reliability, and costs. With the help of technology, our professionally qualified engineers deliver custom PCBA designs that are appropriate for varied end-use such as telecommunications, industrial automation, and renewable energy systems. Entering SHEN CHUANG, you receive not just a PCBA. You will get a PCBA along with other accessories fully synchronized with the ideas of marketing the product. Our advantages are linked directly to the promise of flexibility, the capability to invent and the ability to execute in the industry of PCBA.

Shenzhen Shenchuang Precision Circuit Co., Ltd. was established in March 2011. It is a high-tech enterprise specializing in the production of double-sided and multi-layer printed circuit boards. The company adheres to the business philosophy of "integrity, innovation, efficiency, collaboration and sharing", based on high-tech innovation and efficient human resource management, stimulates technological change and driving force, adheres to scientific, standardized, normalized and procedural quality management, and is committed to continuously improving customer satisfaction and creating a characteristic brand enterprise in the PCB industry.

Ensures accuracy and durability for optimal functionality in bulk orders.

Capable of handling both small and large-scale manufacturing efficiently.

Provides custom designs to meet unique project needs and applications.

Supports single-layer to multi-layer boards for diverse project demands.

Yes, John! Our typical lead time for customized PCBA orders is between 4 to 6 weeks, depending on the complexity of the design and the quantity ordered.

We follow stringent quality control measures, Klaus, including automated optical inspection (AOI), functional testing, and IPC-A-610 standards to ensure high quality and reliability.

Absolutely, Hiroshi! We can handle small batch sizes for prototypes, ensuring you have the flexibility to test and refine your designs without large commitments.

Yes, Ana! Our team of experts can provide design assistance throughout the process, helping you optimize your PCB layout for performance and manufacturability.

We can integrate a wide range of components, Rajesh, including surface-mount devices (SMD), through-hole components, and various types of connectors based on your project requirements.